Supply and demand chain planning and execution have grown in importance over the past decade as companies have recognized that software can meaningfully enhance their competitiveness and improve their financial performance. Sales and operations planning (S&OP) is an integrated business management process first developed in the 1980s aimed at achieving better alignment and synchronization between the supply chain, production and sales functions. A properly implemented S&OP process routinely reviews customer demand and supply resources and “replans” quantitatively across an agreed rolling horizon. The replanning process focuses on changes from the previously agreed sales and operations plan; while it helps the management team understand how the company achieved its current level of performance, its primary focus is on future actions and anticipated results. Adoption of S&OP has increased as software to support the process has become more powerful and affordable and as a growing list of companies demonstrated its value in producing meaningfully improved business results. Even without adopting a full-scale S&OP management approach, companies can benefit from better coordination and collaboration between their supply and demand functions. Software plays an important role here, too, in facilitating this coordination and collaboration.

Steelwedge, founded in 2000, is one provider of it, offering cloud-based software for sales and operations planning as well as for supply and demand planning, related revenue and margin planning. It recently introduced its PlanStreaming platform, which provides a unified space in which organizations and their individual business units can create plans. PlanStreaming is specifically designed to support integrated continuous planning between demand chain roles (sales, marketing and demand planning, to name three), supply chain roles (including supply chain management, purchasing, manufacturing and operations) as well as finance. The software gathers input from both multiple enterprise systems and data sources outside a company to “sense” the condition of the supply and demand chains, incorporates plans and forecasts from multiple perspectives and applies advanced analytics to assess, predict and prescribe the best courses of action. PlanStreaming is designed to apply a continuous planning methodology to supply- and demand chain execution. The objective is to improve execution across the company: higher fulfillment rates with more rapid inventory turns resulting in increased revenues at wider margins.

“Continuous planning” is an approach that uses frequent, short planning cycles that can help organizations achieve greater agility, coordination and accountability in their operations. Such an approach includes establishing an ongoing dialogue between supply- and demand chains as well as finance to track current conditions and how they are evolving. It is an action-oriented methodology and approach to planning processes. To manage planning in such a comprehensive way requires dedicated software that enables flexibility in all phases. Continuous planning requires software to streamline and shorten planning cycles to rebalance the focus of the process from assembling a plan to acting on a plan rapidly and in a coordinated fashion. PlanStreaming addresses these requirements by automating the collection and normalization of data to make it continuously available for analysis. Data can be automatically monitored to provide alerts to risks and opportunities as business conditions evolve. It provides analytical tools that support rapid, action-oriented “what-if” scenario and contingency planning that conforms to a company’s strategic priorities and capabilities.

The need to improve planning processes is there. Our recent benchmark research on next-generation business planning finds limited satisfaction with the planning areas that Steelwedge addresses. Only half of participants that engage in demand planning (54%) said that they are satisfied with their company’s planning process. For sales forecasting the number is 47 percent; for sales and operations planning it is 43 percent; and for supply chain planning only about one-third (35%) said they are satisfied. The leading reasons given for their lack of satisfaction are that plans are not reliable, that processes are too slow and inflexible and that they involve using models that are difficult to build and maintain. We also find that a large majority of participants in our research use spreadsheets for these planning processes, which is likely an important factor underlying the lack of satisfaction. The research also shows that fewer than one in five companies collaborate very effectively in these planning processes. Here, too, dedicated software such as Steelwedge’s that integrates planning processes across multiple functions and business units can support deeper, more consistent collaboration among them.

A defining characteristic of supply and demand chain planning is that the details matter a lot. For example, accurately forecasting total revenue from some product isn’t enough to manage operations well. Companies need to accurately predict what individual customers at each location will want to buy. And they need to correctly identify which products – even down to the individual stock-keeping unit (SKU) – each customer will need. Dedicated software such as Steelwedge facilitates the collection, analysis and communication of this level of detailed information that streamlines planning and reporting to enable action-oriented supply- and demand planning.

Another significant characteristic of this type of planning is that the individual functional groups responsible for supply and demand chain execution have different objectives, which often are at odds with one another. Sales and marketing people want to maximize revenue, which can conflict with the ability of those in manufacturing to produce the goods. Manufacturing units want to maximize efficiency, but too-long production runs of one SKU may lead to stock-outs of another and require more investment in inventories. Rushed deliveries may keep customers happy but cut into profits. Sales and operations planning is a cross-functional process and discipline that is designed to bring all parties involved in supply and demand chain execution into a planning process that mediates the conflicts between these functions to produce a plan that aligns the objectives of each to achieve the company’s strategic objectives. PlanStreaming makes it easier for corporate executives to mediate the different objectives and incentives of the various supply and demand groups in their organization. This enables them to align the integrated plan to a company’s strategy to achieve a more optimal result.

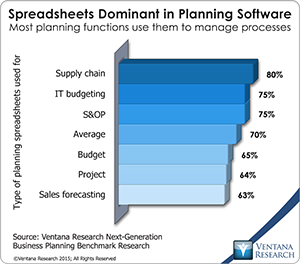

A dedicated software application is superior to using desktop spreadsheets for creating actionable demand and supply plans because it eliminates time-consuming chores that impede effective planning. Creating an organization-wide plan from multiple business units requires integrating the details of individual planning units to create a unified view. Our spreadsheet research determined that even individuals with more than a decade of experience have difficulty combining spreadsheets to create a consolidated view and find the process time-consuming. Arriving at a plan that balances the needs and objectives of individual business units within the corporation’s overall objectives is an iterative process. Integrating desktop spreadsheets often forces companies that rely on them to spend a great deal of time on the mechanics of planning. This of course extends the time required to create a plan and hampers the organization’s ability to respond promptly to changes in supply and demand. In this respect, spreadsheets are a barrier to action-oriented planning. Nevertheless, our business planning research shows that 80 percent of companies use them for supply chain planning, 75 percent use them for S&OP and 63 percent use them to support sales planning. The research also found that more than half of participants in these planning areas say that spreadsheets make it difficult for them to manage their planning process. A core defect of spreadsheets when used for operational planning is that it is difficult to separate units and currency in analyzing and reporting the information that individuals need for their particular role (for instance, looking at input/output ratios in production or logistics or assessing customer profitability). Even for midsize companies, spreadsheets fail to scale to handle the scope and detail needed to support this type of planning.

using desktop spreadsheets for creating actionable demand and supply plans because it eliminates time-consuming chores that impede effective planning. Creating an organization-wide plan from multiple business units requires integrating the details of individual planning units to create a unified view. Our spreadsheet research determined that even individuals with more than a decade of experience have difficulty combining spreadsheets to create a consolidated view and find the process time-consuming. Arriving at a plan that balances the needs and objectives of individual business units within the corporation’s overall objectives is an iterative process. Integrating desktop spreadsheets often forces companies that rely on them to spend a great deal of time on the mechanics of planning. This of course extends the time required to create a plan and hampers the organization’s ability to respond promptly to changes in supply and demand. In this respect, spreadsheets are a barrier to action-oriented planning. Nevertheless, our business planning research shows that 80 percent of companies use them for supply chain planning, 75 percent use them for S&OP and 63 percent use them to support sales planning. The research also found that more than half of participants in these planning areas say that spreadsheets make it difficult for them to manage their planning process. A core defect of spreadsheets when used for operational planning is that it is difficult to separate units and currency in analyzing and reporting the information that individuals need for their particular role (for instance, looking at input/output ratios in production or logistics or assessing customer profitability). Even for midsize companies, spreadsheets fail to scale to handle the scope and detail needed to support this type of planning.

As noted, Steelwedge’s product for S&OP, supply and demand planning is cloud-based. One important advantage of the cloud is that it offers ready access for everyone who might be involved regardless of where they are. Steelwedge also offers mobile capabilities because people who are involved in the process (such as those in field sales, those in warehouse operations or managers and executives) often are on the go yet need to be able to view and approve details without holding up the process.

As noted, Steelwedge’s product for S&OP, supply and demand planning is cloud-based. One important advantage of the cloud is that it offers ready access for everyone who might be involved regardless of where they are. Steelwedge also offers mobile capabilities because people who are involved in the process (such as those in field sales, those in warehouse operations or managers and executives) often are on the go yet need to be able to view and approve details without holding up the process.

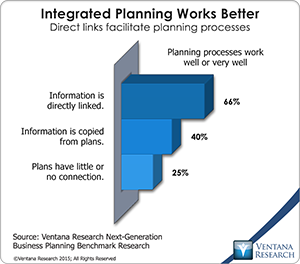

Our research shows that direct links between interconnected plans produces better results. Two-thirds (66%) of companies that have direct links between plans said they have planning processes that work well or very well, compared to 40 percent that copy data manually from one plan to another and just 25% of those that have little or no connection between plans. Steelwedge’s PlanStreaming platform provides the integration point between the various supply- and demand planning groups in a corporation to improve accuracy as well as the effectiveness of its planning process. The quality of planning processes also correlates with the accuracy of the plans: Four out of five companies that plan well or very well said they have plans that are accurate or very accurate, compared to 24 percent that have processes that are managed adequately and just 5 percent that have poor management.

Implementing sales and operations planning or simply achieving better coordination between supply chain planning, demand planning and sales forecasting can be facilitated by a dedicated software platform such as PlanStreaming that supports all of the planning processes as separate activities and addresses the needs of the different groups. This approach allows companies to avoid organizational issues that result from imposing changes on well-established processes because of technology limitations. Such an approach also allows organizations to phase in the technology and to build competence in planning before transitioning to an integrated business planning effort. If the organization is committed to implementing integrated sales and operations planning, it can do so right away if all of the component pieces reside on a single platform.

Most companies would benefit from being able to plan more effectively for supply and demand chains. Those that face long or complex supply and demand chains need to adopt S&OP to ensure that the inherent differences in the objectives of various planning groups are mediated by senior management. (This is not easy because an S&OP culture must be instituted.) I recommend that companies that want to improve their supply or demand chain planning process evaluate Steelwedge. I include both those that want to move off spreadsheets to make their supply chain and sales planning faster and more nimble, and those that want to begin to implement an S&OP discipline or move their S&OP efforts from spreadsheets to a more capable, easier-to-use platform.

Regards,

Robert Kugel – SVP Research